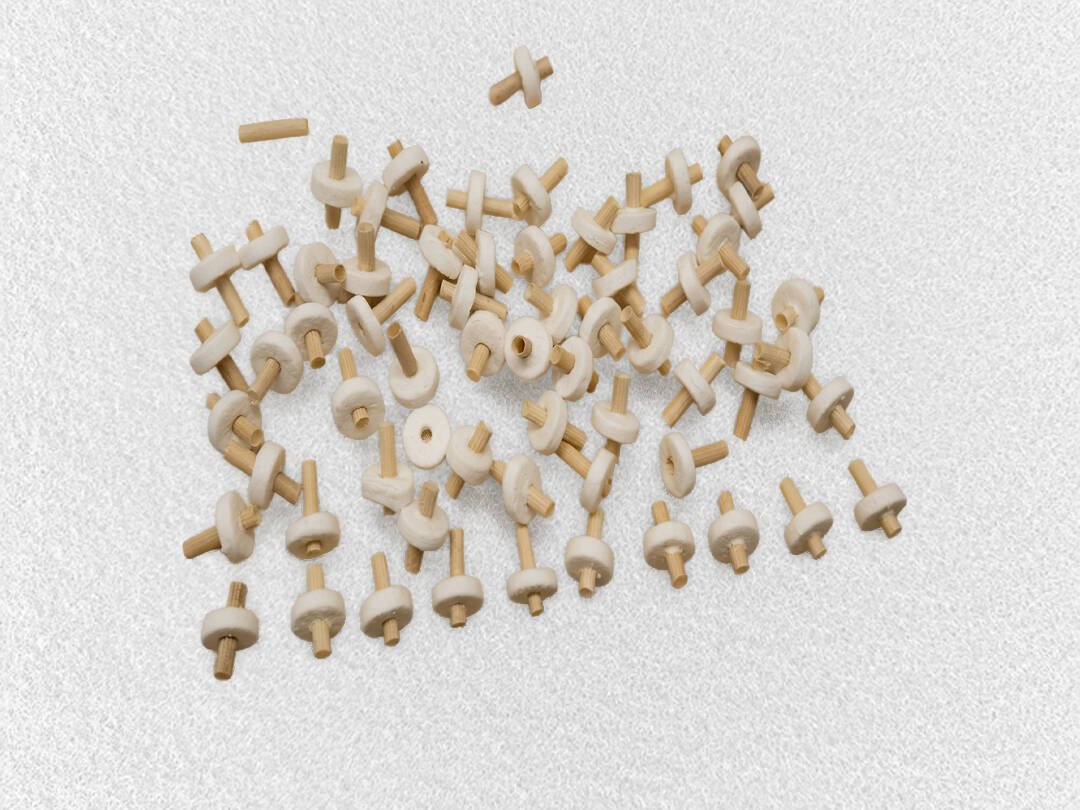

Ceramic Washer With Ferrule

Ceramic Ferrule Washer Assembly is used in core room on cylinder Head water jacket core. It is placed on water jacket core so as to ensure proper seating of mould on the core assembly. Ceramic washer gives air tight assembly due to its compressive nature. Most of the Cylinder Block and Head manufacturing foundries reject castings due to blow holes. Foundry experts try to reduce defects by providing extra gas vents, increasing pouring temperatures and/or time etc. While manufacturing Cylinder Heads and water jacketed Blocks, wedge plugs core prints are provided on water jacket cores. To remove the gas from wedge plug core prints, cores are drilled and gas vents are provided on cope moulds to allow core gas to escape from the water jacket cores. If there is any gap between core print and mould, there are chances to spread the core gas in mould cavity, which in turn accumulate in mould area and casting gets rejected due to blow hole.